![[Translate "Ireland"] Kragarmregal-Anlage](/fileadmin/_processed_/7/4/csm_Cantilever_racking_002_c7ed3e5c7d.jpg)

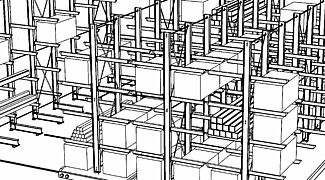

Quality and comprehensive service speak for themselves. OHRA can look back on over 40 years of experience as an established manufacturer of heavy-duty racking systems, and offers an impressive all-round service: From consulting to the manufacture and assembly of racking systems. The cantilever rack is the most important product in the range.

With customised racks and an extensive range of accessories, we offer a complete solution for the storage of long goods and heavy loads. Everything: Made in Germany.

Advantages of cantilever racking from OHRA

The sophisticated racking systems for heavy loads or long goods are individually manufactured by OHRA according to your requirements – in Germany. They are powder-coated to a high standard or hot-dip galvanized for outdoor storage. Even when fully loaded, the cantilever racking system remains permanently stable and ensures a high level of safety for your staff and your customers. There are specific solutions for every product and every industry. The racks for long goods differ in height, usable depth, load capacity, or profile thickness depending on requirements.

A basic distinction is made between single-sided and double-sided cantilever racking system:

- Rack columns and cantilever arms made of solid, hot-rolled IPE steel profiles

- Plug-in system, height-adjustable arms

- Freely movable cantilever arms protect goods and racks in the event of collisions

- We offer both single-sided and double-sided solutions

- High-quality powder coating protects the material and ensures a particularly long service life

- Also available with roof, rear panel, and rain gutter in the outdoor area

- Optional hot-dip galvanized version for outdoor storage

The cantilever principle is simple, yet fully thought through by OHRA.

Everything you need to know at a glance

These are vertical steel supports with horizontally projecting roof cantilevers. The stored goods are placed on these arms. They are used for the storage of especially long objects such as pipes or beams (long goods).

They are available in either single-sided or double-sided versions. Single-sided cantilever racking is usually integrated along the walls of the warehouse or set up close to them. In the double-sided version, they allow access from both sides and maintain their stability through even weight distribution and a stable basic construction. Both can also be anchored in the ground.

In addition to the simple versions, there are also models with a roof, which offer the stored goods protection from the weather if they are used outdoors.

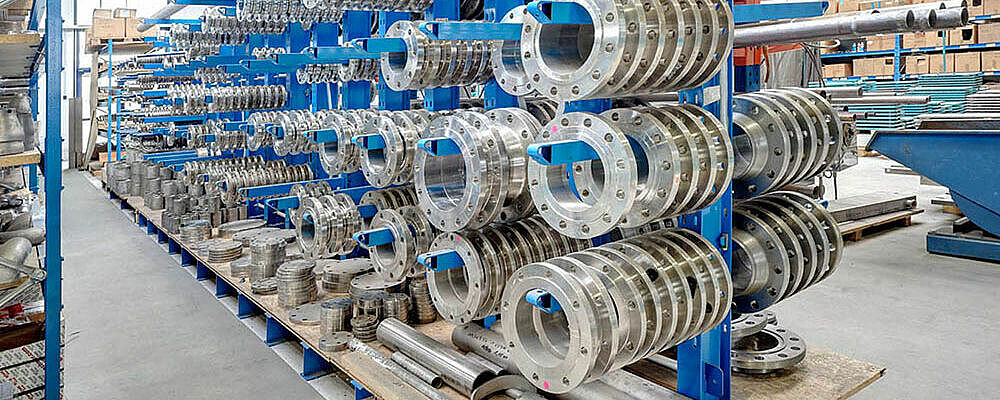

Today, cantilever racking made from hot-rolled steel profiles can be found in almost all industries:

- In the timber trade or building material trade for the storage of squared timber, boards, stones, pipes, and profiles,

- in the steel trade where sheet metal formats and heavy steel profiles have to be stored securely,

- in joinery and carpentry workshops as storage for heavy chipboards,

- but also at car recyclers,

- marinas,

- furniture and kitchen manufacturers,

- and many other sectors where it is important to store a lot on a small footprint.

here are specific solutions for every product and every industry. Depending on requirements, they differ in height, usable depth, load capacity, or profile thickness. This is why OHRA always produces heavy-duty shelving according to the individual requirements and specific specifications of its customers.

Cantilever racking is an extremely strong storage system for storing long goods and heavy loads. This includes, for example, wooden panels, metal sheets, profiles, beams or steel elements, building materials or even end-of-life vehicles and all types of heavy loads.

Our variants, your choice

Simple functional principle – many useful versions:

Cantilever racking with roof

In outdoor areas, cantilever racking with a roof is the right choice for your long goods that do not necessarily have to be stored in an enclosed warehouse. In addition to the load requirements, we take into account the snow and wind loads in your region when calculating the structural strength of the storage system, and dimension the rack profiles and the rack roof accordingly. We advise you right from the start: from planning to roofing. We also support you with your building permit – with drawing materials and statics on request.

Single-sided cantilever rack

The single-sided cantilever rack is usually positioned under a roof or in front of a wall. It is operated from only one side.

The stable design allows a free-standing construction.

If the cantilever rack is planned as a single-sided rack, it can be closed at the rear and sides when used outdoors – for example with trapezoidal sheet metal or wood.

Double-sided cantilever racking

The double-sided cantilever racking consists of the same column profile as the single-sided option. However, both sides of the rack are fitted with bases and cantilever arms. This gives you twice the storage space. This advantage makes the double-sided solution even more economical.

Heavy-duty cantilever racking

Heavy loads are a challenge for any rack. The cantilever racking from OHRA therefore consists of hot-rolled steel profiles for all load-bearing elements. The product benefits of this racking system become even more apparent as load requirements increase. With standard arm loads of up to 2,500kg and with support loads of up to 10,000kg, it can also handle heavy loads without any problems.

Mobile cantilever racks

In a mobile cantilever racking system, the rows of racks are directly connected to each other, with no free space in between. Only when you want to access your stored items, you can move the desired racks manually or electrically, thus creating access. By using mobile racks from OHRA, you can make optimum use of your limited storage space and organise your products efficiently. The space saving also provides a clear overview of your stored goods and the various product groups, which saves time and resources.

Cantilever rack for long goods

Cantilever racks for long loads are suitable for storing particularly long goods. A rack for long goods can be designed both as a vertical storage system and as a horizontal storage system. The decisive factor when selecting a system is the intended use and the available space in the warehouse. The cantilever racks are e.g. ideal for pipes. Access is quick and you have a good overview of the different lengths and varieties. The vertical racking system can be installed near the working station or in sales rooms to present your goods to the customers.

Other versions of cantilever racking systems

Other cantilever rack designs from OHRA offer customised solutions for unique storage needs, including special applications such as rack-clad warehouses, mezzanine floors and tile presentations. Discover our other cantilever rack variants with a wide selection of materials, stability, safety, and expandability.

Efficient storage solution for Marles

Leading timber house manufacturer Marles relies on cantilever racks from OHRA to make optimum use of its storage capacities. The robust shelving systems enable space-saving and safe storage of wooden materials. By flexibly adapting the racks, Marles was able to make its processes more efficient.

Technical details

The construction of our cantilever racking consists of solid, robust, hot-rolled steel profiles that are particularly strong, safe, and durable. The main elements (columns, cantilever arms, base) are powder-coated to a high quality for indoor use. All other components are strip galvanized in accordance with DIN 10346. Hot-dip galvanizing of components in accordance with DIN EN ISO 1461 for outdoor use.

Anchoring of the racks indoors with galvanized anchors, outdoors with stainless steel anchors.

Product features of cantilever arms:

- Hook-in version, adjustment grid 100: 100mm

- Flexible and free arm movement (e.g. type K60K+H), thus protecting the cantilever arm and your goods from damage

- Quick hooking and unhooking in almost horizontal position, e.g. K60 K+H

- High-quality hook-in claw, specially hardened version

- Standard colours RAL 5015, 2002, 3000, 6011, 7035

- No impact edges on the storage surface due to protruding connecting plates on the cantilever arm --> therefore no damage to the goods during the storage and retrieval

- Arm deflectors on the cantilever arms in accordance with regulations

- Prepared to accommodate roll-off safety

- Prepared for the use of an adjusting screw

Product features Column/base:

- Double-sided column perforation for the arm fixing (adjustment grid 100: 100mm)

- Screwed flush with the column base, ensuring full-surface support on the base, without protruding connecting plates. Therefore, no damage during the storage and retrieval

- Components can be easily replaced in the event of warehouse modifications or repairs

- Tire protection thanks to a bevel on the column base (standard in the K60 system)

Our racking systems comply with DIN 18800-7 and the current guidelines of the trade association for storage facilities and equipment (BGR 234), are safety-tested, and have a corresponding GS seal of approval.

Are you looking for the right racking system or have you already found the right one? We will be happy to advise you and send you a quote on request.

Accessories for OHRA cantilever racking

Various accessories are available for the extended configuration of your cantilever rack. These can either be supplied retrospectively or at the time of ordering. These include gratings, roll-off safety in heavy and light versions, arm bridges, saddle tubes, and much more. Below, you can see a selection of the solutions we have implemented.

Request a quotation

We will be happy to advise you and send you a quote on request.

![[Translate "Ireland"] [Translate "English"] Kragarmregale](/fileadmin/_processed_/7/4/csm_Cantilever_racking_002_7cdaa73d6b.jpg)